Current Research

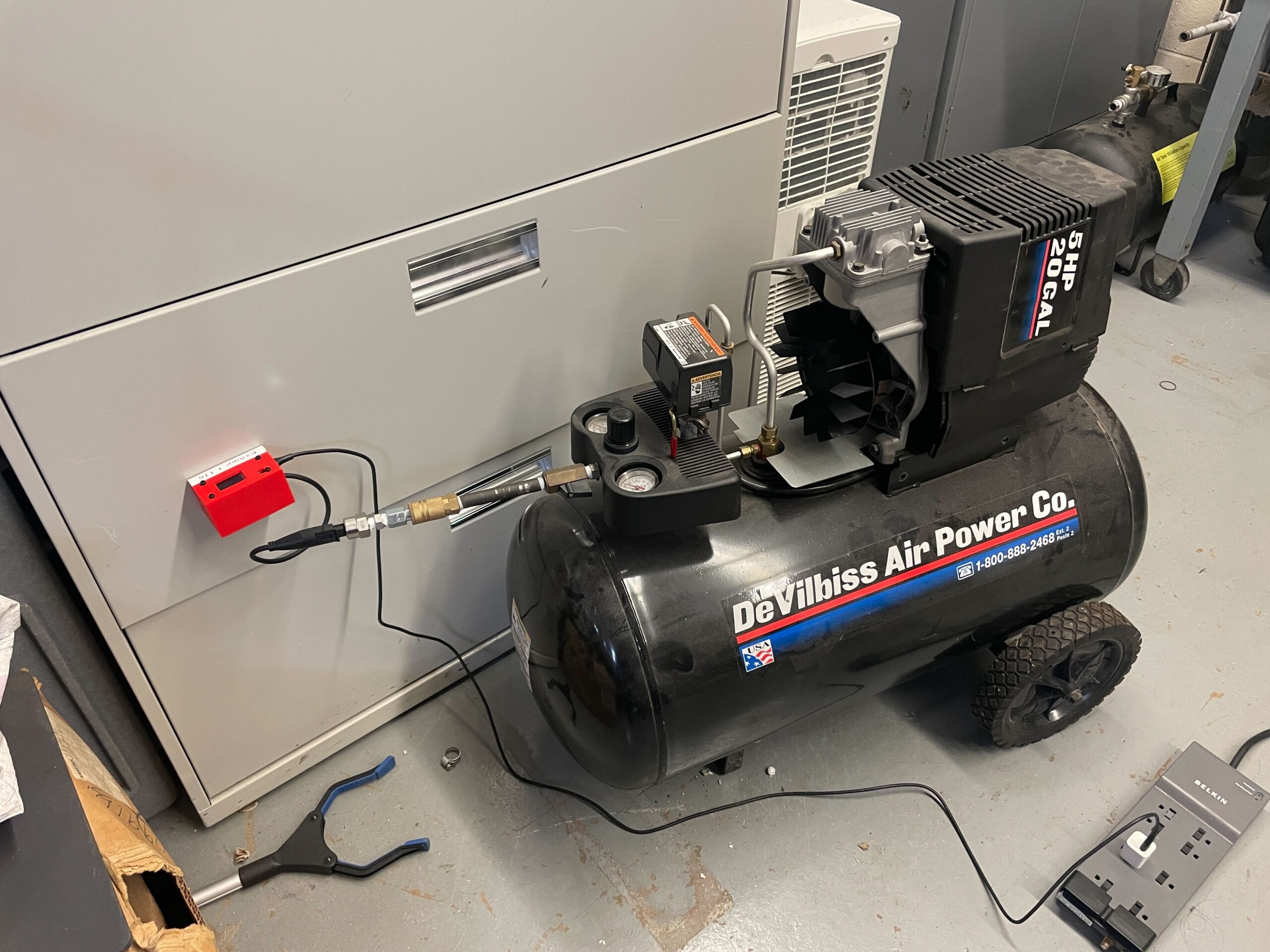

Performance Analysis and Leak Detection of Compressed Air System Using IOT

The research is on compressed air systems by using continuous data monitoring through IOT devices to obtain the data and process which is useful assessing the compressed air system for leak detection, losses in pipe and for performance study. The data can be also used for predictive maintenance and fault detection.

Chintan Lakhani, MS in Mechanical Engineering

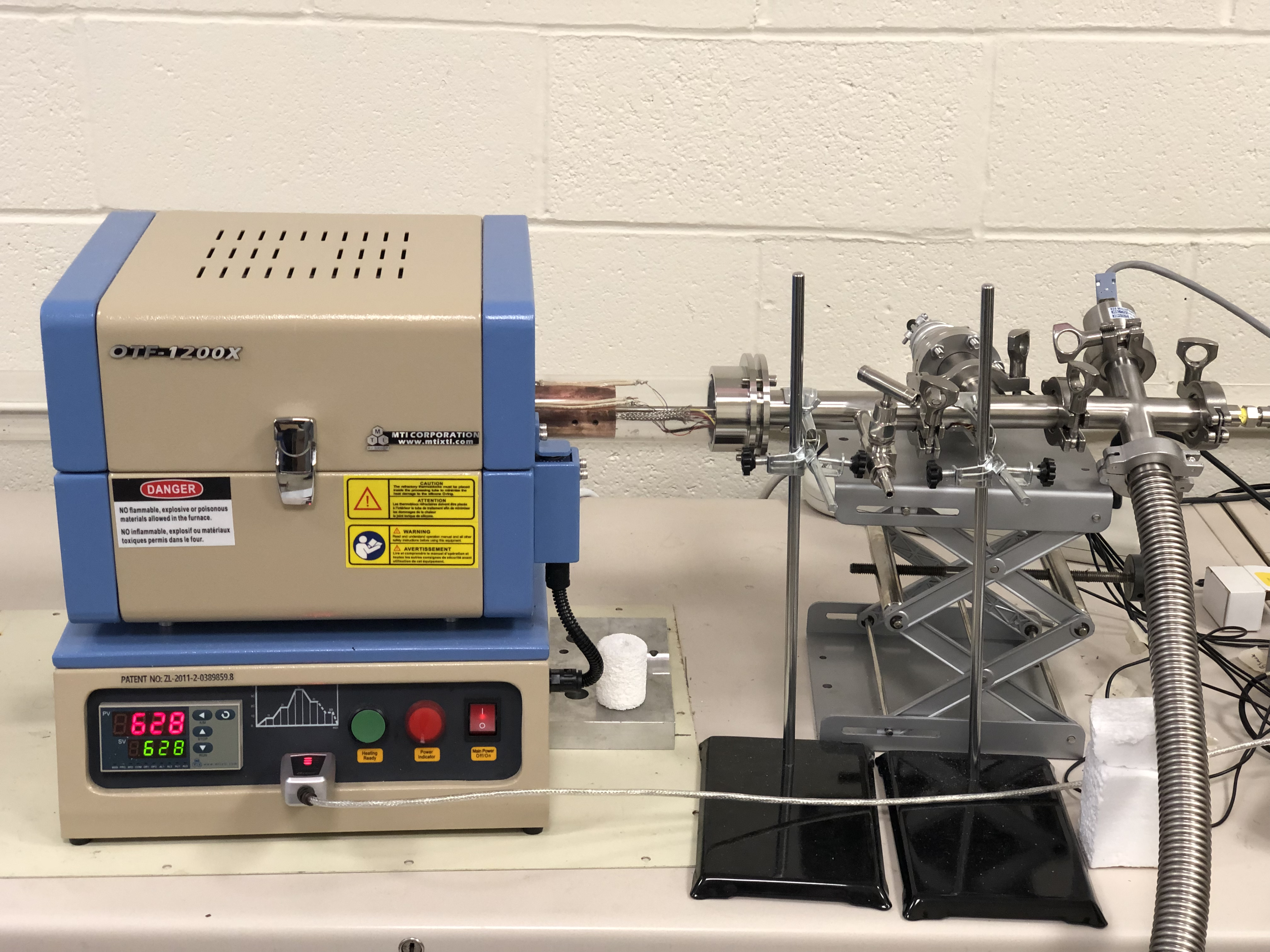

Microwatt Resolution Ultra-High Temperature Differential Calorimeter

Calorimetry of an exothermic reaction is a current of great interest, but requires a high-resolution heat flow measurement. In this work, a fabrication of microwatt resolution ultra-high temperature differential calorimeter studies the heat flow measurement of the reaction between hydrogen and metal hydride. Hydrogen can be stored in different ways; this study focuses on solid-state storage using metal hydride.

Eslam Al Qawasmeh, MS in Mechanical Engineering

A Computational Study of Latent Heat Thermal Energy Storage Performance with the Addition of Additively Manufactured Triply Periodic Minimal Surface Lattice

This research optimizes latent heat thermal energy storage (LHTES) using triply periodic minimal surface lattices via additive manufacturing. It characterizes the effects of lattice type, density, storage volume, and heat transfer fluid speed on LHTES efficiency. Additionally, it compares LHTES with other energy storage methods based on power output, charge/discharge rates, energy storage density, applications, and limitations. The aim is to enhance LHTES performance and broaden its applicability in energy storage systems.

David Garner, MS in Mechanical Engineering

Past Research

Microgrids and Transformative Blockchain Potential - A CAES Study of the Rutgers Grid

Blockchain technology’s fully reliable hierarchical ledger capabilities makes it a perfect candidate for alternative technology applications outside of its traditional cryptocurrency use. Here at CAES we are looking into specific use cases for blockchain. More specifically, if the Rutgers microgrid – which includes a roughly 28MW Busch Campus load, a 15MW Cogeneration Plant and 9MW of solar panels – were to act as an island-able, presuming microgrid and sell excess generation. An economic opportunity cost-benefits analysis is being performed as well as how the promotion of renewable energy could increase the value of our green energy. A secondary focus is to calculate and derive the pedigree classification factors which include efficiency, emissions, loss of attributes, reliability and a few other factors of our Rutgers CHP plant. We are hopeful in finding relations that can give us a new pricing model for excess energy to be sold to other plants or back to the grid.

Kelly Baber, MS in Mechanical Engineering

Solar PV

A combination of research and IAC program quality assurance regarding photovoltaic recommendations. 15-minute data, otherwise known as interval data, is of particular interest. Figuring out the best way to line up interval data from a plant's electrical usage with photovoltaic generation provides the most realistic results but is not always possible. Softwares such as PVWatts and NREL's SAM have been investigated. This research is all about understanding the benefits and drawbacks of current practices in an attempt to figure out the best practice.

Christopher Murphy, MEng in Energy Systems

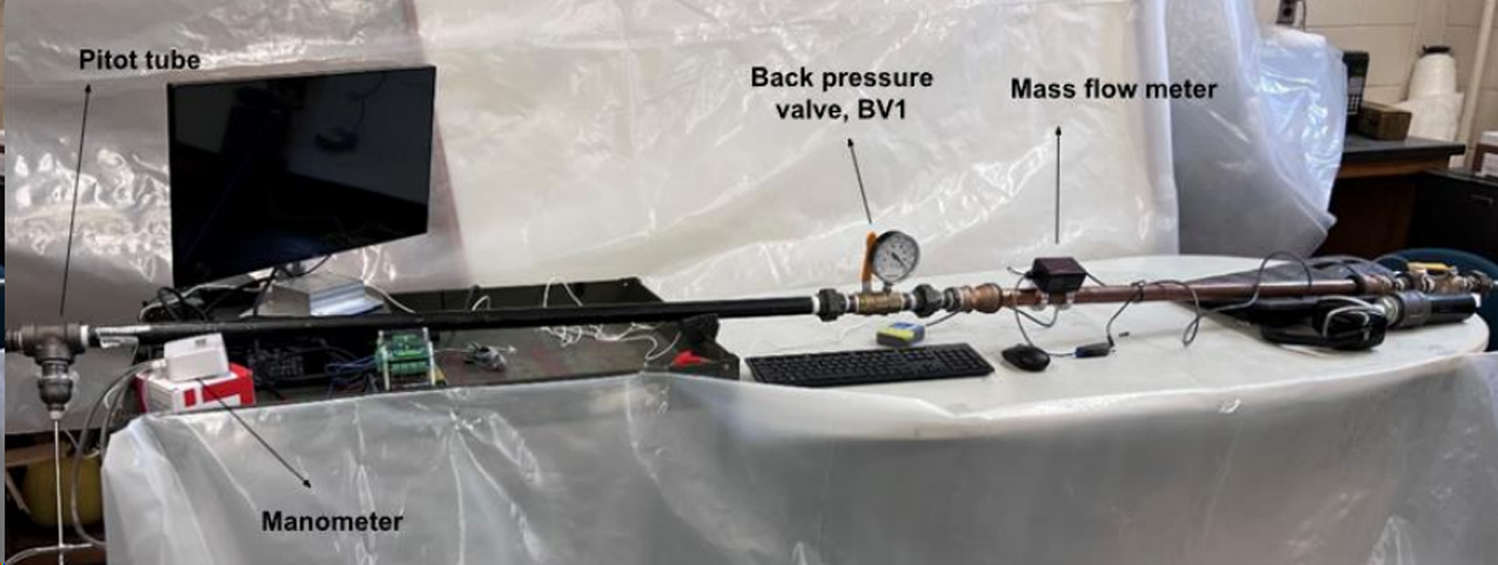

An Evaluation of Air Flow Measurement Opportunities in Industrial Compressed Air Systems

This research studies the role of flow meters in industrial compressed air systems and develop a facility for mass flow meter evaluation. Flow meter placement was studied with respect to different system layouts. Ideal placement was determined based on type of layout and location of equipment. This also enabled baselining performance and helping maintain overall system operation. Flowmeters downstream of every compressor gives individual and total compressed air generation. On the demand side, a multiple loop and trunk layout with only one compressed air line from the main loop is a good layout design for flowmeter placement and compressed air delivery.

Subhash Kungumaraj, MS in Mechanical Engineering

Value Proposition for SMART Retrofit Solutions

Smart retrofitting can include automation, simulation, data collection and optimization of manufacturing processes. It is strongly coupled with the concept of Industrial Internet of Things (IIoT). The adoption of smart retrofitting in manufacturing is found to be modest despite their benefits. Lack of structured value proposition approach by application is suspected as one of the major reasons for lower adoption. In this topic we develop the value proposition matrix and apply the same to ten low-hanging fruit smart retrofit applications. This would provide a framework for understanding the full value a smart retrofit applications can provide. The matrix can also be used to rank the smart retrofit solutions. The value proposition matrix will further be quantified for the use cases by collecting the data through smart IIoT data collection devices.

Aditya Mairal, PhD Student

Distributed Wind Conference (DWEA)

The 2023 Distributed Wind Conference (DWEA) took place from February 27th to March 1st 2023 in Washington, DC. This conference is for leaders of the distributed and community wind industry to showcase their sector of the wind industry to an audience of policy makers, agency staff, and renewable energy industry leaders to promote new business opportunities and relationships as well as gain insight into potential new markets. Eslam Al Qawasmeh, David Garner, Evan Bickel, and Dr. Todd Rossi from Rutgers Center for Advanced Energy Systems (CAES) attended the DWEA Conference as part of the REpowering Schools’ (REpS) National Small Wind Turbine Research Project sponsored by FedEx. During the fall semester of 2022, Dr. Todd Rossi merged the research project with the Rutgers mechanical engineering alternative energy course in which 55 senior undergraduate students were introduced to solar, wind and other renewable energy sources; they received hands-on, experiential learning on the fundamentals of wind turbine testing, evaluation, and validation with the small wind turbine donated by REpS. Additionally, CAES will

continue to test the wind turbine in a hybrid wind-solar energy system. At the DWEA Conference, the CAES team presented on the turbine research conducted along with 5 other universities who were part of the REpS program. Students had the chance to network with industry professionals and discuss career opportunities and professional guidance.

Eslam Al Qawasmeh, Graduate Student

Industrial Demand Response Utilizing Lithium Ion BESS

Battery Energy Storage Systems (BESS) represent an enormous market and savings potential for industrial needs, particularly in demand response as greater energy production needs put greater strain on energy grids across the country, driving up demand pricing as high as $43/kW in some manufacturing municipalities in California. Lithium Ion technology is the current industry standard, but represents significant economic investment for small and medium sized manufacturing companies. Though battery cost is rapidly dropping, companies still hold methodology and pricing close to the vest. CAES is conducting research into the technology, sizing, price-points, and case-identification for commercial demand response solutions of Lithium Ion BESS.

Sara Neiss, Graduate Student

Design Optimization for Wave Energy Conversion Co-Located with Offshore Wind Farms

Hydropower is a relatively old technology, but Wave Energy Converters (WECs) are an emerging industry, experiencing rapid expansion in the last 5 years and are currently positioned where wind was about 8 years ago. In the field of marine energy capture, they represent a safer, simpler, and more economic alternative to tidal and offshore wind energy. While wind farms are a more mature technology and industry than current WECs, energy provided by ocean waves is denser, more consistent, and more predictable than wind, holding greater earning potential. Furthermore, WECs provide significant ancillary benefits to nearby marine structures, especially wind farms. CAES is conducting research into the optimization of Wave Farm designs co-located and sharing infrastructure with offshore wind to produce the greatest economic yields from power generation per square foot as well as stimulate further development in the Wave and Wind Farm industries.

Sara Neiss, Graduate Student

Utility Demand Charges

The US Energy Information Administration (eia.gov) estimates that demand charges in the commercial sector account for 30 to 70 percent of monthly electric bills, although rates vary considerably by utility, location, season, and building type. One proposed way to curtail high demand charges is by programmatically scheduling flexible loads to even out power consumption over the demand-setting window. The research at Rutgers’ CAES is focused on developing and testing a demand limiting Model Predictive Control (MPC) algorithm for unitary HVAC systems called Unit Coordination (UC). The application coordinates flexible rooftop unit (RTU) loads to avoid coincident runtimes. The MPC algorithm is designed to toggle RTU operation by setting an optimal demand ceiling that forces the zones to “take turns” when flexibility is present. The optimizer can be configured and implemented using only the onsite thermostats, where control decisions are relayed to the thermostats via API as setpoint adjustments that turn units on or off. No physical setup needed. The research explores the scope of viable MPC use cases in Building Energy Management and seeks to uncover real world technical challenges and algorithm deficiencies.

Joshua DeVenezia, Graduate Student

Dropwise Condensation Modification by Surface Functionalization and Droplet Removal

Through functionalization of a thermally conductive, hydrophilic solid substrate's surface, by dual micro and nano scale roughening and reduction of surface energy to induce superhydrophobicity, the rate of condensate production and heat transfer is modified for dropwise condensation on the cooled surface, when condensate is continuously removed from the condensing surface.

SMART Manufacturing

SMART Manufacturing is an emerging field that uses sensors to connect industrial machinery within a manufacturing plant to the internet for the purposes of data analytics and remote status monitoring. CAES is working to develop a process and protocol for identifying and recommending SMART projects to manufacturers within the Industrial Assessment Center Program, including questions to ask plant personnel, observations to make during the plant tour, and measurements to take throughout the day. Currently, CAES is studying the applications of the ABB Smart Sensor - a non-invasive instrument that relays the physical data of a traditional motor to the user via bluetooth technology. The sensor’s capacity for short-term data collection and the modeling potential of said data is being investigated.

Novel Applications of Fluidized Beds

Fluidized beds have enormous potential to improve environmental performance of coal combustion. At CAES, we have studied a wide range of topics related to fluidized bed performance optimization including minimization of temperature fluctuations and the effects of vibration on the system. In addition, we primarily focused on mixing in fluidized beds and breaking up large agglomerates. Designing the size and shape of these objects requires accurate modelling of drag and buoyancy effects, and development of an understanding of the “unfluidized hood” which appears on top of any large submerged object.

Publicatons

- Siddika Pasi, Dr. Michael R. Muller, Kelly Baber, Sara Neiss, “Study of Blockchain Technology's Potential to Deliver Transformative Disruption to An Aging Grid“, 2019 ACEEE Study on Energy Efficiency in Industry

- Siddika Pasi, Sara Neiss, Julie Sieving, John Smegal, “A More Inclusive Gender Diverse Workforce and Shifting Paradigm on Leadership in the Energy Efficiency Industry“, 2019 ACEEE Study on Energy Efficiency in Industry

- Prakash Rao, Michael R. Muller, Garan Gun, “Conducting a Metering Assessment to Identify Submetering Needs at a Manufacturing Facility”, CIRP Journal of Manufacturing Science and Technology, Volume 18, Pages 107-114, 2017

- Prakash Rao and Dr Michael R. Muller, “Characterization of De-Fluidized Regions in the Wake of Submerged Objects in a Small Particle Fluidized Bed”, Powder Technology, vol. 243, pp 53-58, 2013

- Dr Michael R. Muller, J. F. Gardner, M. B. Muller, D. Shrestha, “The Energy-Water Nexus: Implications for Energy Efficiency”, Industrial Energy Technology Conference, New Orleans, May 2014

- Siddika Pasi, “Investigating the Impact of Boiler Aging In Replacement Decisions", 2007 ACEEE Study on Energy Efficiency in Industry